-

Glutinous Aroma Tribute Tip Qimen An Tea

$14.00 USDGlutinous Aroma Tribute Tip Qimen An Tea

$14.00 USD -

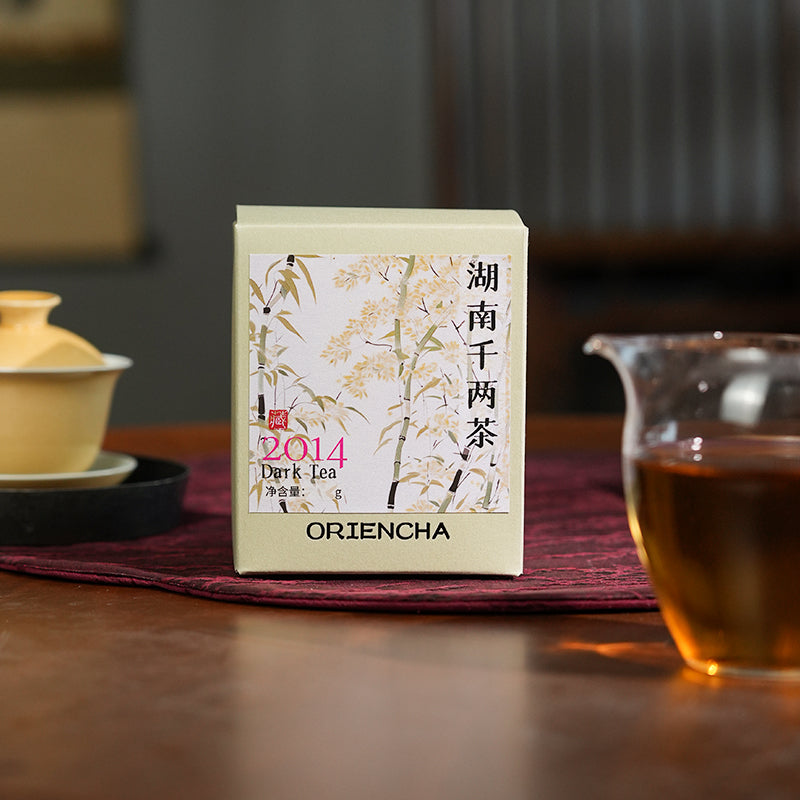

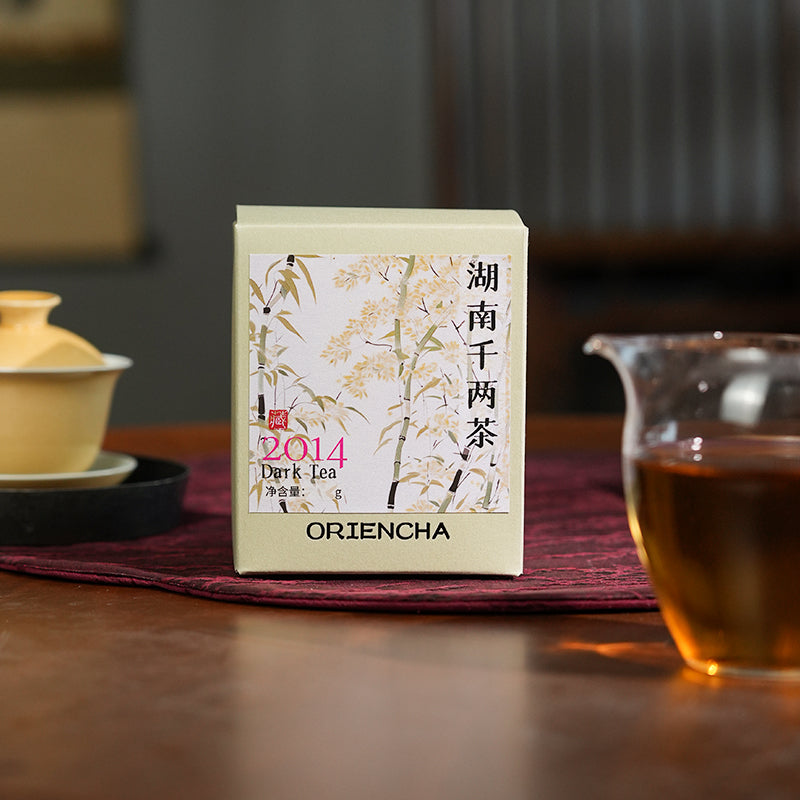

2014 Hunan Qian Liang Tea

$28.00 USD2014 Hunan Qian Liang Tea

$28.00 USD -

Sale

Sale2012 Golden Flower Fu Tea

$32.00 USD$29.00 USD2012 Golden Flower Fu Tea

$29.00 USD$32.00 USD -

Sale

Sale2012 Zuiyin Tianlu Anhua Dark Tea

$32.00 USD$29.00 USD2012 Zuiyin Tianlu Anhua Dark Tea

$29.00 USD$32.00 USD -

The Beauty of Grand Wilderness | Anhua Dark Tea Sample Set

$29.00 USDThe Beauty of Grand Wilderness | Anhua Dark Tea Sample Set

$29.00 USD -

2013 Tianjian Anhua Dark Tea

$23.00 USD2013 Tianjian Anhua Dark Tea

$23.00 USD -

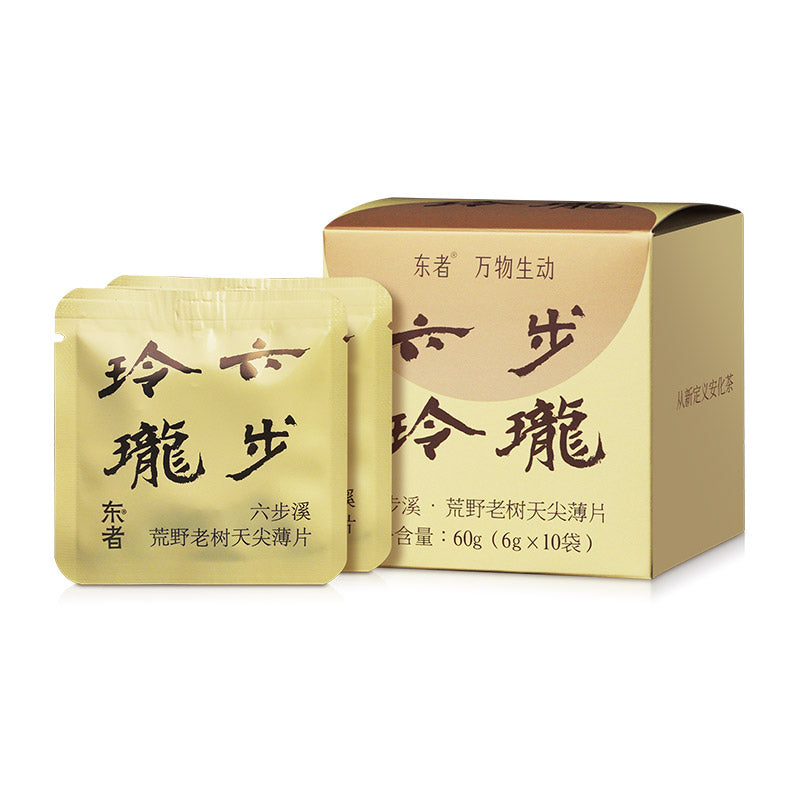

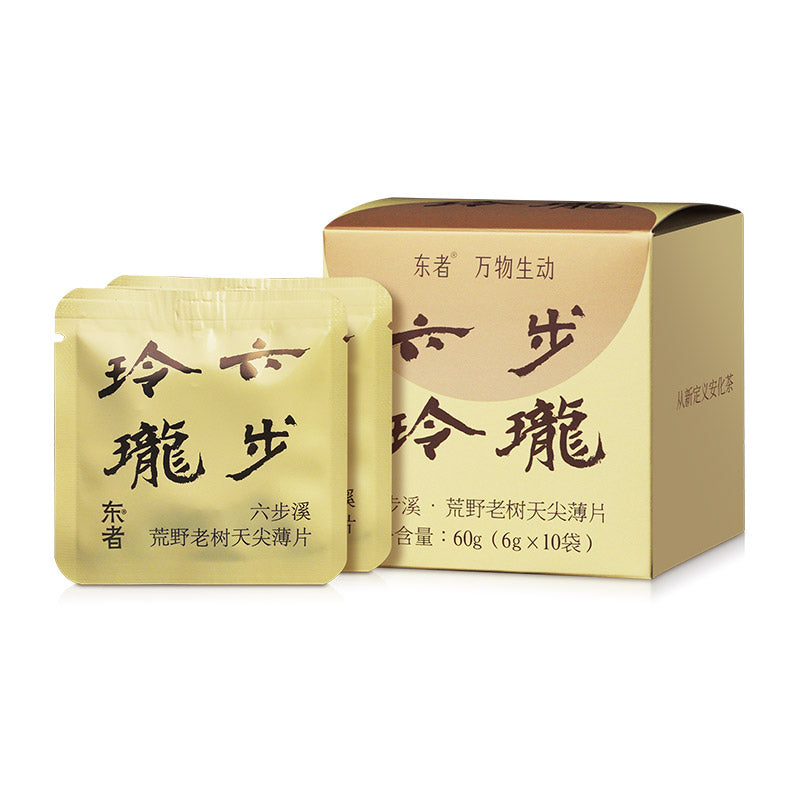

Liubu Linglong Anhua Dark Tea | Wild Old Tree Tianjian Tea Thin Disc

$29.00 USDLiubu Linglong Anhua Dark Tea | Wild Old Tree Tianjian Tea Thin Disc

$29.00 USD -

2016 Yu Qilin Anhua Dark Tea Cake

$129.00 USD2016 Yu Qilin Anhua Dark Tea Cake

$129.00 USD -

2019 Gaoma Cangjuan Centuries Old Tree Qianliang Tea Cake

$168.00 USD2019 Gaoma Cangjuan Centuries Old Tree Qianliang Tea Cake

$168.00 USD